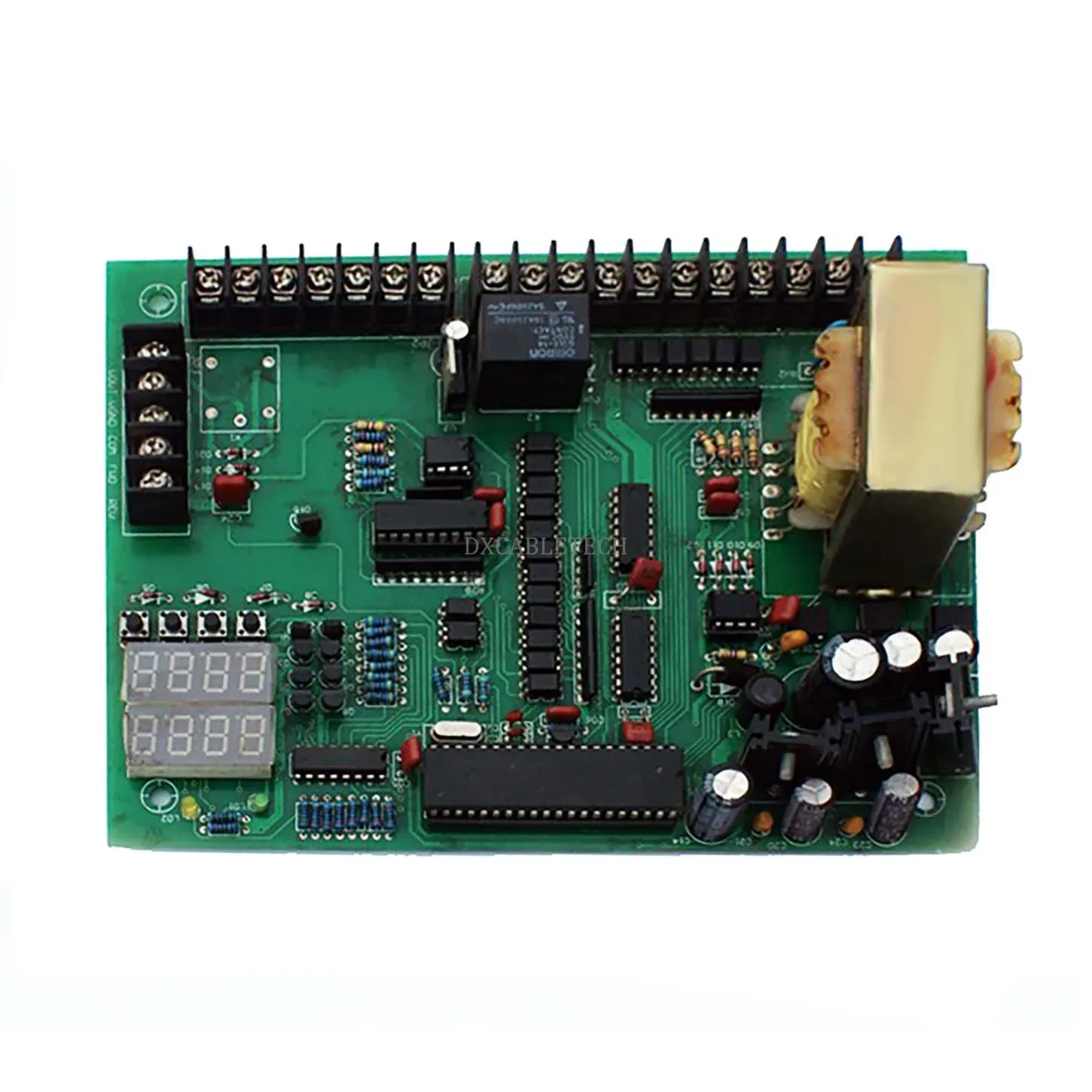

Cable Stranding Machine Manufacturers: Quality & Development

In the dynamic world of cable manufacturing, quality and innovation are paramount. Cable stranding machine manufacturers understand this imperative and consistently strive to deliver equipment that meet the highest standards. These manufacturers utilize cutting-edge methods to ensure reliable performance, producing stranded cables with exceptional integrity.

Moreover, leading cable stranding machine manufacturers are at the forefront of innovation, constantly exploring new ways to optimize their products. This commitment to advancement results in units that are more efficient, while also minimizing environmental impact.

- The industry's leading manufacturers prioritize quality control throughout the entire production process.

- From material selection to final testing, meticulous attention to detail ensures that each machine meets stringent industry standards.

- Customers can depend on these manufacturers to provide high-quality cable stranding machines that deliver exceptional performance and longevity.

Wire Twisting Machines: Precision Engineered for Excellence

Wire twisting machines represent the pinnacle of engineering prowess. These devices are carefully engineered to create high-quality twisted wires with outstanding precision. Their durable construction and cutting-edge design allow them to handle a broad range of wire diameters and materials, guaranteeing consistent and accurate results. From industrial applications, wire twisting machines play a fundamental role in interlinking our modern world.

Automated Cable Stranding Technologies: Boosting Efficiency

In the fast-paced world of wire and cable manufacturing, efficiency is paramount. Modern cable stranding solutions are revolutionizing the industry by streamlining production and boosting output. These advanced systems leverage robotics to precisely strand wires, resulting in reliable cable products.

Advantages of automated cable stranding include increased production speeds, leading to significant operational improvements. Furthermore, these systems enhance accuracy, contributing to a efficient manufacturing process.

- Companies across diverse sectors are increasingly implementing automated cable stranding solutions to meet the growing demand for high-quality cables.

- Investing these technologies not only streamlines operations, positioning businesses for long-term success.

Heavy Duty Wire Twisting Machines: Industrial-Grade Performance

In the demanding realm of industrial manufacturing, precision is paramount. Heavy duty wire twisting machines are engineered to deliver exceptional capability in even the most demanding production environments. These robust machines employ powerful motors and sophisticated drive systems to ensure consistent twisting action, generating high-quality wire components with exceptional strength and integrity.

Heavy duty wire twisting machines are designed to handle a wide range of wire gauges, from fine strands to heavy-duty cables, accommodating diverse applications. Features such as adjustable rates, variable torque settings, and automatic wire transport systems enhance their flexibility.

- Producers of heavy duty wire twisting machines prioritize safety and worker comfort, incorporating features such as emergency stop buttons, safety guards, and ergonomic designs.

- These machines often integrate with automated production lines, streamlining workflows and increasing overall efficiency.

- Heavy duty wire twisting machines are essential tools in a wide array of industries, including automotive, electronic, and manufacturing.

Specialized Cable Strands: Engineered Precisely

In the demanding world of cable manufacturing, precision is paramount. That's why selecting a custom cable stranding system can be the solution to fulfilling your unique requirements. Whether you need bundled cables for industrial applications, a customized system can improve your assembly process. Through working with experienced engineers, you can develop a system that effectively integrates the precise materials and construction required for your application.

- Advantage1: Description1

- Benefit2: Explanation2

- Benefit3: Explanation3

High-Speed Wire Twisting Equipment

In today's rapidly evolving manufacturing landscape, meeting demanding production quotas with a focus on exceptional quality is paramount. Such requirements necessitate this goal, manufacturers often turn to high-speed wire twisting equipment, sophisticated machinery designed to produce tightly wound, durable wire assemblies. These systems leverage cutting-edge technology and automation to increase output while maintaining the highest standards of precision and reliability.

From simple two-conductor twists to complex multi-stranded cables, high-speed wire twisting equipment can handle a extensive range of applications across diverse industries. Automotive components, for instance, heavily rely on these machines to create robust and reliable connections. Moreover, the ability to integrate with existing production lines allows for seamless integration and streamlined manufacturing processes.

Leading Cable Stranding Machine Suppliers: Global Reach

The global cable stranding machine market is a dynamic and thriving industry with numerous suppliers vying for prominence. Amongst these, several companies have emerged as leading providers, renowned for their robust machines and comprehensive reach. These industry giants address the needs of a diverse clientele, encompassing sectors such as wire twisting machine telecommunications. Their commitment to delivering high-quality products and exceptional customer service has reinforced their position as key players in the global market.

- A vast array of factors contribute to the success of these leading suppliers, including their sophisticated manufacturing capabilities, strong research and development initiatives, and a dynamic approach to meeting evolving market demands.

- In addition, their international footprint enables them to efficiently serve customers in distant locations, solidifying their position as essential partners in the global cable industry.

Wire Twisting Machines: From Single Conductors to Multicores

Wire twisting machines perform a crucial role in the manufacturing process of electrical cables. These versatile tools coil individual conductors together, creating reliable multicore cables vital for various deployments. From simple single-conductor cables to complex bundled configurations, wire twisting machines offer accurate twisting capabilities to fulfill diverse industry demands.

- Fundamental wire twisting machines were primarily designed for single conductor twisting, creating cables used in basic applications.

- The evolution of wire twisting machines has led to the development of more sophisticated models capable of handling multicore cable production.

- Modern machines employ computer-controlled systems to achieve excellent accuracy and productivity in the twisting process.

Reliable Cable Stranding Solutions: Proven Track Record robust

When it comes to cable stranding, you demand the most effective solutions. Years of experience and a steadfast commitment to excellence have solidified our reputation as a premier provider of cablestranding solutions. Our proven track record speaks for itself, with countless satisfied customers who rely on our advanced technology and meticulous craftsmanship to guarantee exceptional results.

- From basic stranding configurations to complex multi-conductor designs, we offer a wide range of options to meet your specific needs.

- Select from a variety of materials, including copper, aluminum, and stainless steel, to achieve optimal performance in your applications.

- Our skilled engineers work closely with you throughout the process, providing expert guidance and support to ensure complete satisfaction.

At [Your Company Name], we understand that consistency is paramount. That's why we utilize only the highest quality materials and employ rigorous quality control measures at every stage of production. Our cable stranding solutions are designed to withstand harsh environments and provide long-lasting performance.

Advanced Wire Twisting Technology: Shaping the Future

The manufacturing/production/fabrication industry is constantly evolving/progressing/advancing with innovative/groundbreaking/cutting-edge technologies. One such advancement/development/innovation that is revolutionizing wire processing is state-of-the-art/advanced/sophisticated wire twisting technology. This technique/method/process allows for the precise/accurate/controlled manipulation of wires, creating/producing/forming intricate and complex/durable/robust shapes with unprecedented accuracy/precision/detail.

- Applications/Uses/Implementations of this technology span/reach/extend across a wide range of industries, including electronics/telecommunications/automotive, where high-performance/reliable/efficient wire connections are crucial/essential/vital.

- Furthermore/Additionally/Moreover, the ability to twist/coil/wind wires with granular/fine/meticulous control opens up new possibilities for designing/engineering/developing compact/efficient/space-saving electrical components and structures/assemblies/systems.

- As/With/Through this technology continues/advances/develops, we can expect/anticipate/foresee even more innovative/groundbreaking/revolutionary applications in the future, transforming/shaping/redefining the landscape of wire processing and beyond/furthermore/ultimately.

Identifying the Right Cable Stranding Machine: A Comprehensive Guide

A crucial aspect of cable manufacturing is selecting the appropriate cable stranding machine for your specific needs. This decision impacts wire strength, flexibility, and overall durability. To ensure you purchase a machine that meets your requirements, consider factors such as the type of cable you produce, production volume, wire gauge, and your budget. Explore various machine types, including rotary, straight-wire, and specialized stranding setups, to find the perfect match for your cable usage.

A well-chosen cable stranding machine will enhance your production efficiency while delivering high-quality cables that meet industry standards.